04/08/2025

Instructions for strapping tools – explained step by step

Whether in logistics, warehousing, or production – when it comes to securely bundling packages, pallets, or boxes , strapping tools for PET & PP strapping or strapping tools for textile strapping are indispensable. Manual strapping tools, in particular, offer a flexible and cost-effective solution for small to medium-sized packaging tasks. This article provides clear strapping tool instructions with practical tips . We also provide a compact strapping tool explanation as well as tips for safe handling and maintenance .

What is a strapping tool? – A brief explanation

A strapping tool is a tool for securing loads using strapping . It tensions the strap, fixes it mechanically or thermally, and then cuts it . Depending on the design, a distinction is made between:

- Manual strapping tool – ideal for mobile use without power

- Semi-automatic strapping tools – for small series

- Fully automatic machines – for industrial applications

In this strapping machine explanation, the focus is on the operating instructions for manual strapping machines , which are particularly suitable for simple applications.

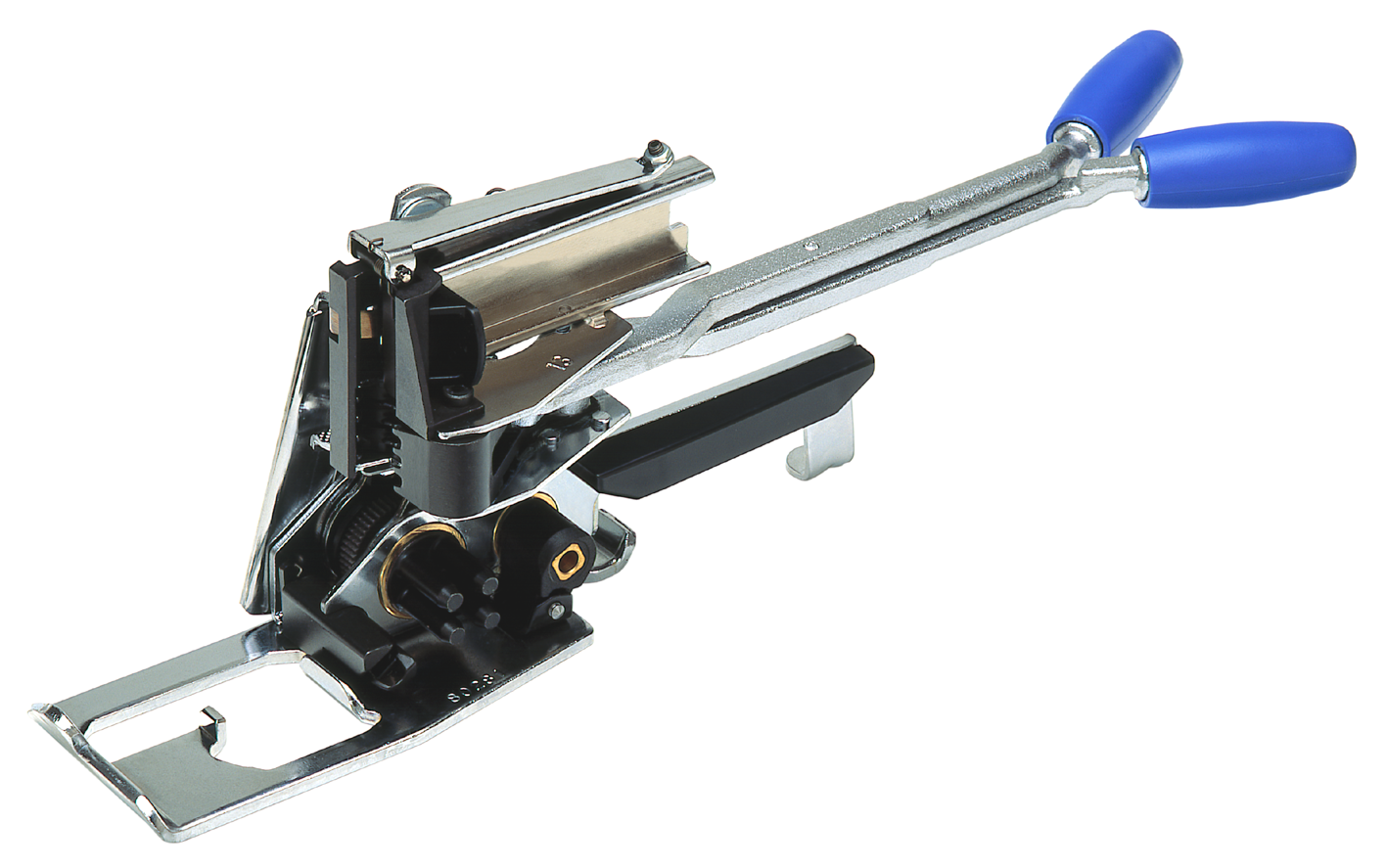

Structure of a manual strapping device

A typical manual strapping tool consists of the following components:

- Tension lever – for tightening the strap

- Cutting mechanism – for cutting the tape

- Tape guide – for safe insertion

Most machines are designed for PP (polypropylene) or PET (polyester) strapping . The operating instructions for a manual strapping tool should therefore always indicate the appropriate strap types and closures .

Strapping tool instructions – step by step

Here follows the practical strapping tool instructions for the safe use of a manual strapping tool:

1. Preparation

- Choose the right strapping band.

- Cut a piece of tape of sufficient length – it must be able to completely enclose the package.

- Place the strap under the package and guide the ends upwards.

2. Insert tape

- Insert both ends of the tape into the device according to the markings.

- The active band strand is usually passed through the device first, followed by the loose end.

3. Tension

- Operate the tensioning lever until the strap is taut around the packaged goods.

- Make sure the strap does not twist or slip.

4. Close

- Place a clasp on both ends of the ribbon.

- Press the locking mechanism or operate the squeeze device.

- For devices with friction welding, the fixing is achieved by heat and pressure.

5. Cutting

- Use the integrated cutting mechanism to cleanly cut off the excess tape end.

- Remove the device carefully.

Safety instructions for operation

The operating instructions for strapping tools should always be observed – especially with regard to:

- Hand protection when clamping and cutting

- Regular checking of the clamping force

- Cleaning the cutting and clamping mechanism

- Use only for suitable tape and seal types

An improper device can not only endanger the package but also lead to injuries.

Advantages of a manual strapping tool

- No electricity required → can be used anywhere

- Low acquisition costs

- Easy maintenance

- Robust and durable

With the correct application according to the operating instructions, many packaging tasks can be completed quickly and reliably.

Conclusion: Strapping tool explanation & instructions

A strapping tool is an indispensable tool in transport and packaging logistics. Manual strapping tools are ideal for small businesses or occasional use. Following the strapping tool instructions will ensure safe, efficient, and professional work . Always ensure you use the correct strap and perform regular maintenance and safety checks .

Would you like a free initial consultation on the products in the Sandax range ? Simply fill out this form.: