18/02/2025

Befestigung und Einbau von Airlineschienen – Eine Schritt-für-Schritt-Anleitung

Airline rails , also known as lashing rails , have become an indispensable part of the world of logistics and transport. These flexible rail systems enable easy and secure cargo securing , whether in vans, trailers, or mobile homes. In this article, we'll show you how to properly attach and install airline rails to ensure maximum safety and functionality.

What are airline tracks?

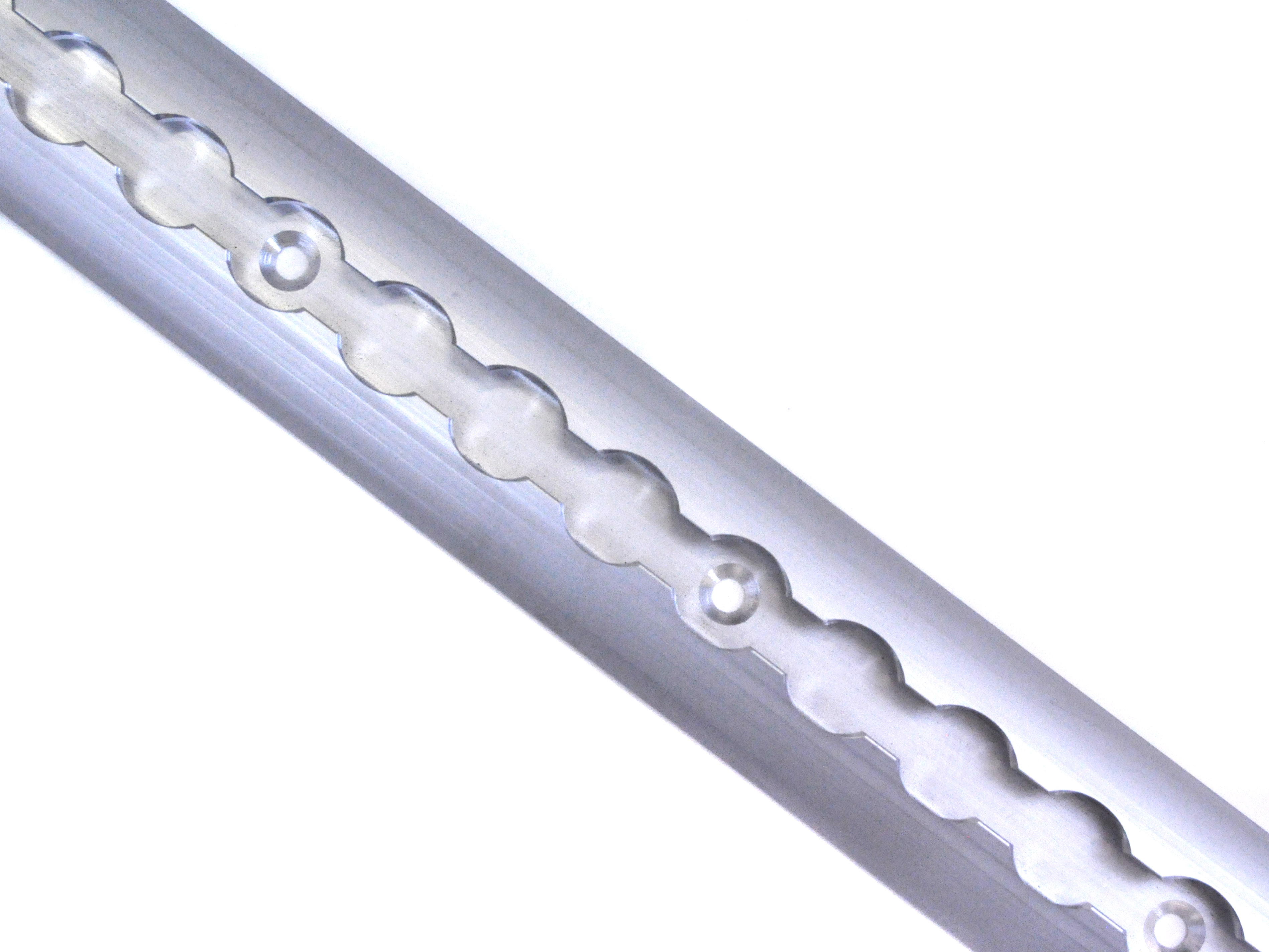

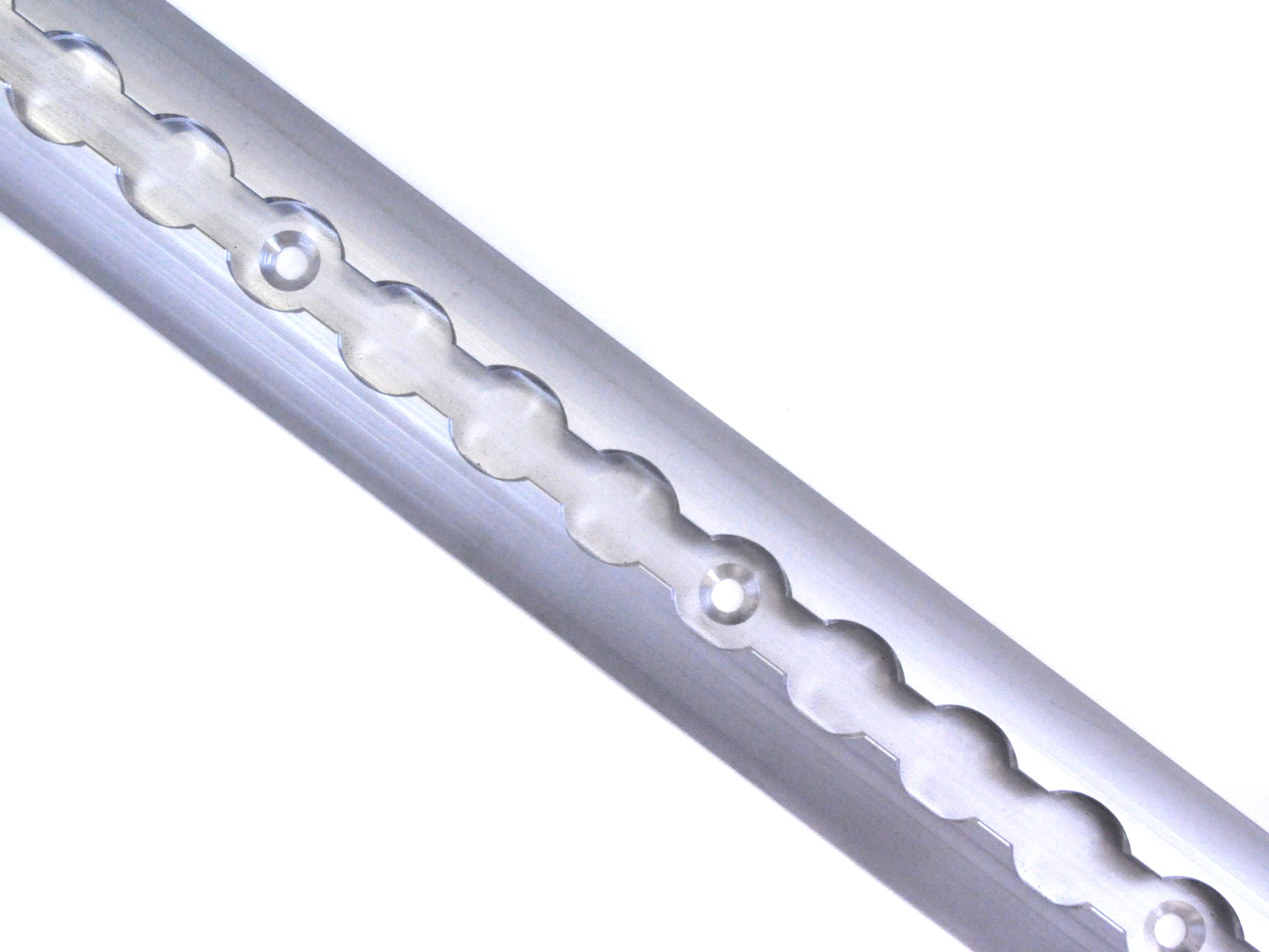

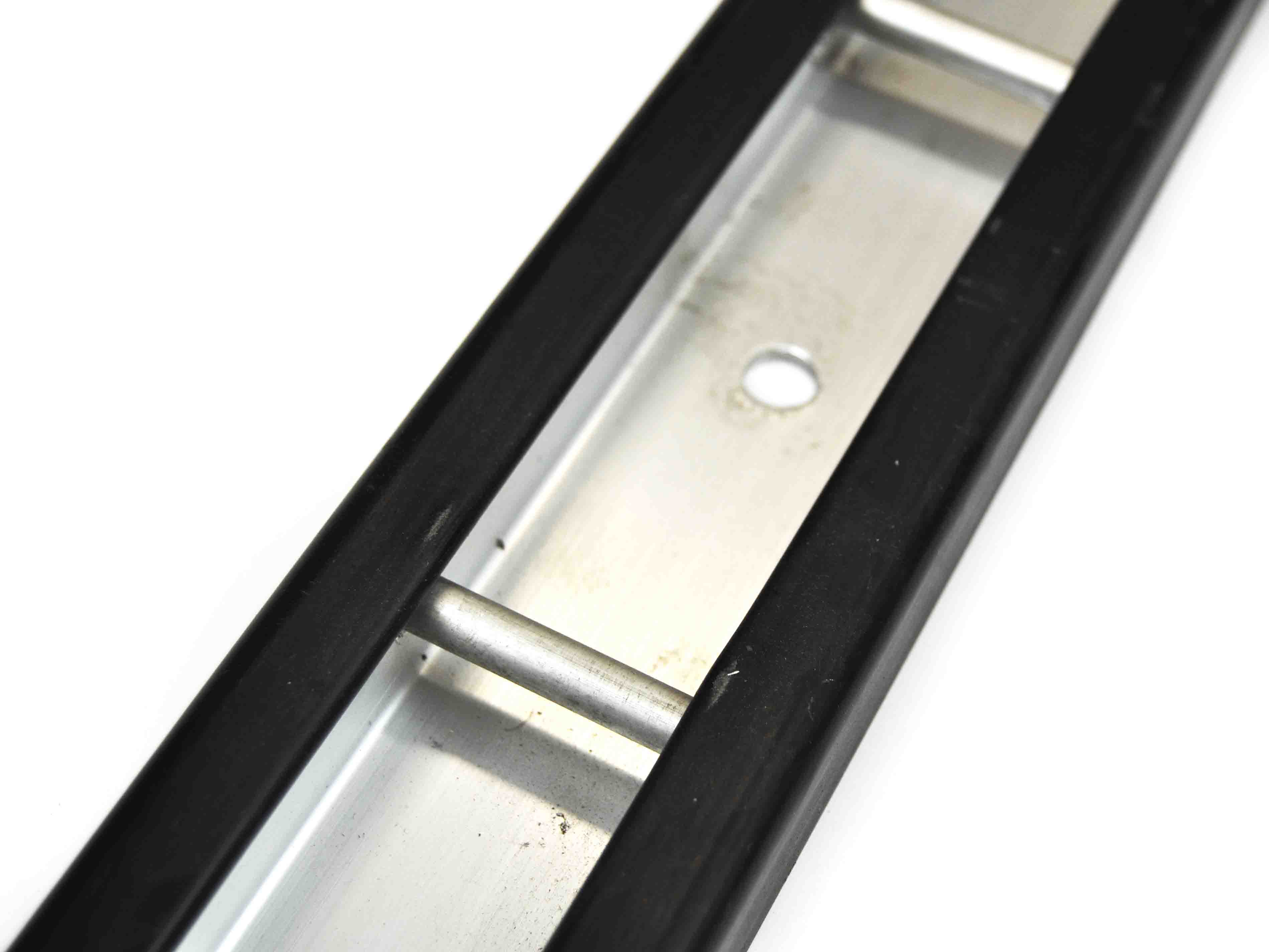

Airline rails are narrow, usually aluminum rail systems with special openings that allow for flexible positioning of lashing straps or attachment points. They are available in various versions, including flat, recessed, or rounded models , which can be customized to suit the application.

Areas of application for airline rails

- Vans and commercial vehicles : securing cargo and tools.

- Motorhomes and campers : Flexible attachment of furniture or equipment.

- Trailers and trucks : Securing heavy or bulky loads.

- Hobby and leisure : securing bicycles, motorcycles or outdoor equipment.

Step-by-step assembly instructions

1. Planning and preparation

- Determine the area of application : Consider where the airline rail will be mounted (floor, walls or ceiling).

- Plan your application : Consider the type and size of the load and the position of the attachment points.

- Check the mounting surface : Make sure the surface is stable, load-bearing and free of obstructions.

2. Mark rail position

- Place the airline rail in the desired location.

- Mark the position of the drill holes with a pencil. Ensure even spacing, usually 10–15 cm, to distribute the load evenly.

3. Drill holes

Drill the marked holes through the mounting surface:

- Tip : For metal surfaces, use a suitable metal drill bit and cool the drill bit if necessary.

- When working on vehicles, be careful not to damage any electrical wiring or bodywork.

4. Deburr edges

Deburr the drilled holes to remove any sharp edges. This prevents damage to the screws and protects against corrosion.

5. Attach the airline rail

- Place the airline rail over the drilled holes and secure it with screws, nuts and washers.

- For vehicles, you can also use sealing compound or silicone to protect the rail from moisture.

6. Check stability

- Tighten all screws and check that the rail is firmly in place.

- Test the rail by inserting lashing straps or other fasteners and applying a slight load.

Tips and tricks for perfect installation

- Pay attention to material quality : Use high-quality, rust-proof screws and nuts, especially for outdoor use.

- Additional reinforcement : For heavy loads, you can use reinforcement plates to better distribute the load.

- Use modularity : Combine different lengths and positions of the rails to achieve maximum flexibility.

- Regular maintenance : Check the airline rails regularly for tightness and possible damage.

FAQ: Airline rails/lashing rails fastening & assembly

What methods are there for attaching airline rails?

Depending on the application, airline rails can be screwed, riveted, or glued with special adhesive . The most stable and durable option is screwing them to a solid surface such as metal or wood . For lighter applications (e.g., motorhome interiors), professional gluing is also an option. Rivets are a solution when screwing is not possible.

How do I attach airline rails to a trailer or van?

Mark the mounting locations, drill the appropriate holes, deburr the edges, and secure the rail with stainless steel screws and, if necessary, reinforcement plates . For box walls, a blind rivet gun can also be used. On aluminum vehicles, contact corrosion should be avoided by using suitable materials for screws and washers.

How much weight can airline rails support?

Depending on the model and fastening method, the load capacity ranges from 500 kg to over 2 t per rail . The decisive factors are the combination of material thickness, installation location, and approved accessories (e.g., fittings, eyelets, lashing straps). For heavy loads, the manufacturer's specifications and maximum tensile forces should be observed .

How often should airline tracks be inspected or maintained?

Regular visual inspection for tightness, deformation, or material damage is recommended – ideally before every long journey and after unusual stress . If defects or corrosion are detected, fasteners and, if necessary, the entire rail must be replaced.

How can I retrofit airline rails in a trailer, van or motorhome?

Retrofitting is easily possible. Select the required rail type (standard, heavy-duty, recessed, or surface-mounted) based on the load and installation location, check that the mounting locations are free of cables or obstructions , drill holes, attach the rails, and secure them with screws or rivets. Glued rails are suitable for lighter applications if necessary, but should be carefully prepared.

What accessories are available for airline rails?

Numerous accessories are available for airline rails, such as fittings , lashing eyes, locking bars, spacers, and T-nuts, enabling flexible load securing . Depending on the application, appropriate components are used for maximum flexibility and safety.

Conclusion on fastening and installation of airline rails

Installing airline rails is an investment in safety and functionality that pays off in many ways. With proper planning and precise installation, you create a flexible base for load securing that will provide you with reliable service for many years.