Strapping Instructions: Step-by-step instructions for using strapping

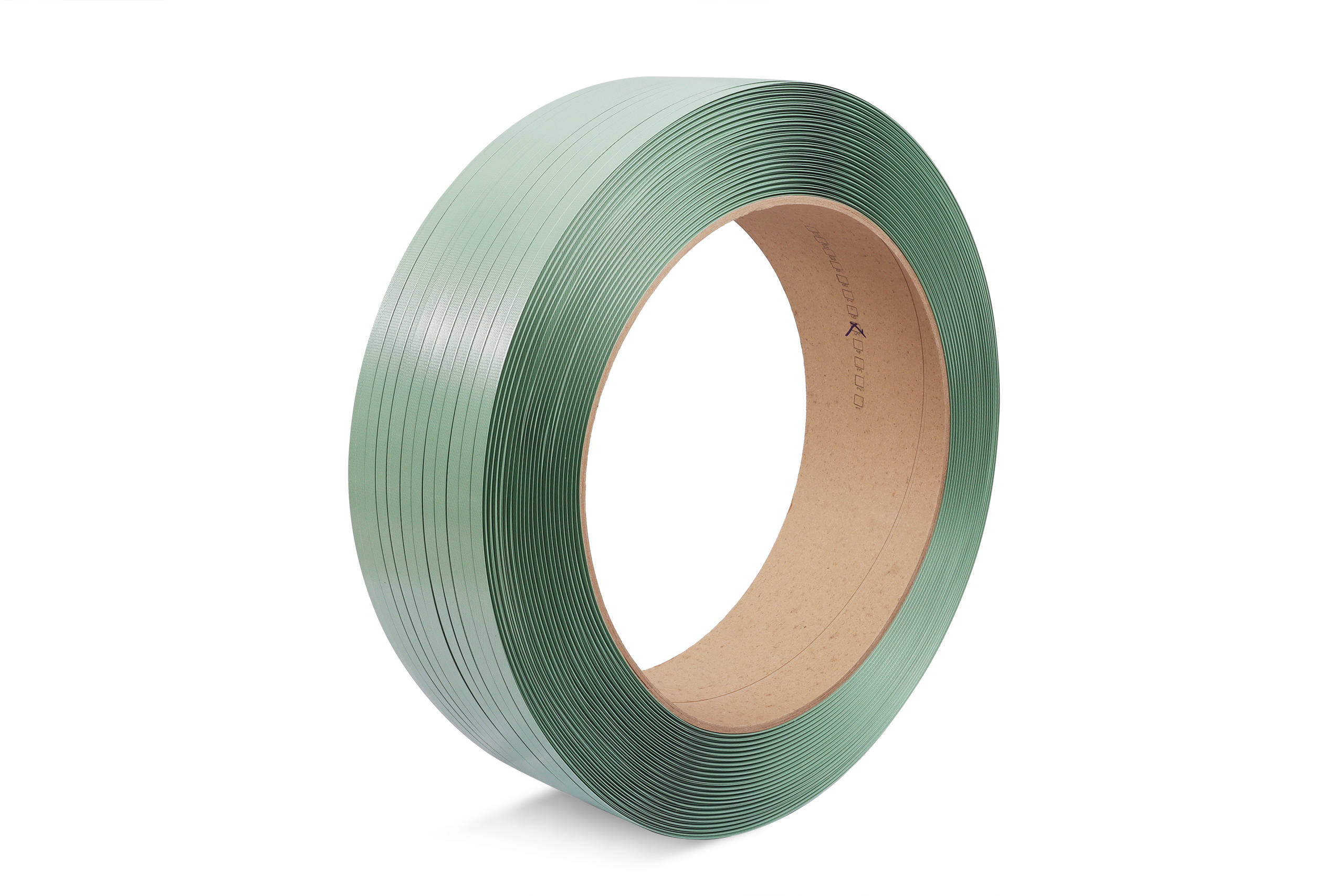

Strapping is often used to secure products and packages during transport or storage. A

step-by-step guide can help make the process efficient and safe. First, the

strapping should be wrapped around the product or carton as tightly as possible. The handle should then be placed on top of the package, and the strap should be pulled through the metal sealing device and pulled taut. The

sealing pliers should then seal the two ends of the strap to prevent the strap from coming loose. It is important to work carefully and precisely to ensure that the product or carton is not damaged during transport.

Safety tips for using strapping

The use of strapping is essential in many industries for the safe transport of goods and loads. However, there are also risks that can be avoided. Therefore, some important safety tips are crucial: Use only

durable and suitable straps , ensure sufficient tension when strapping, and regularly check the straps' fit. You should also wear

appropriate protective equipment when cutting straps and never pull the straps over sharp edges. With these simple measures, you can increase safety when using strapping and prevent accidents.

Tips for choosing the right strapping

Selecting the right strapping for a specific task is crucial for the safe transport of goods. Depending on the weight and size of the load, as well as the transport conditions and means of transport, it may be necessary to choose a specific strapping. The most important tips for selection are knowing the strap's load-bearing capacity,

using compatible processing equipment , and considering quality standards. It's also important to consider using strapping of the correct width and thickness, as well as the correct tension band. Following these tips can ensure

safe and effective packaging .

FAQ: Instructions for strapping band and strapping tool

How do you use strapping correctly?

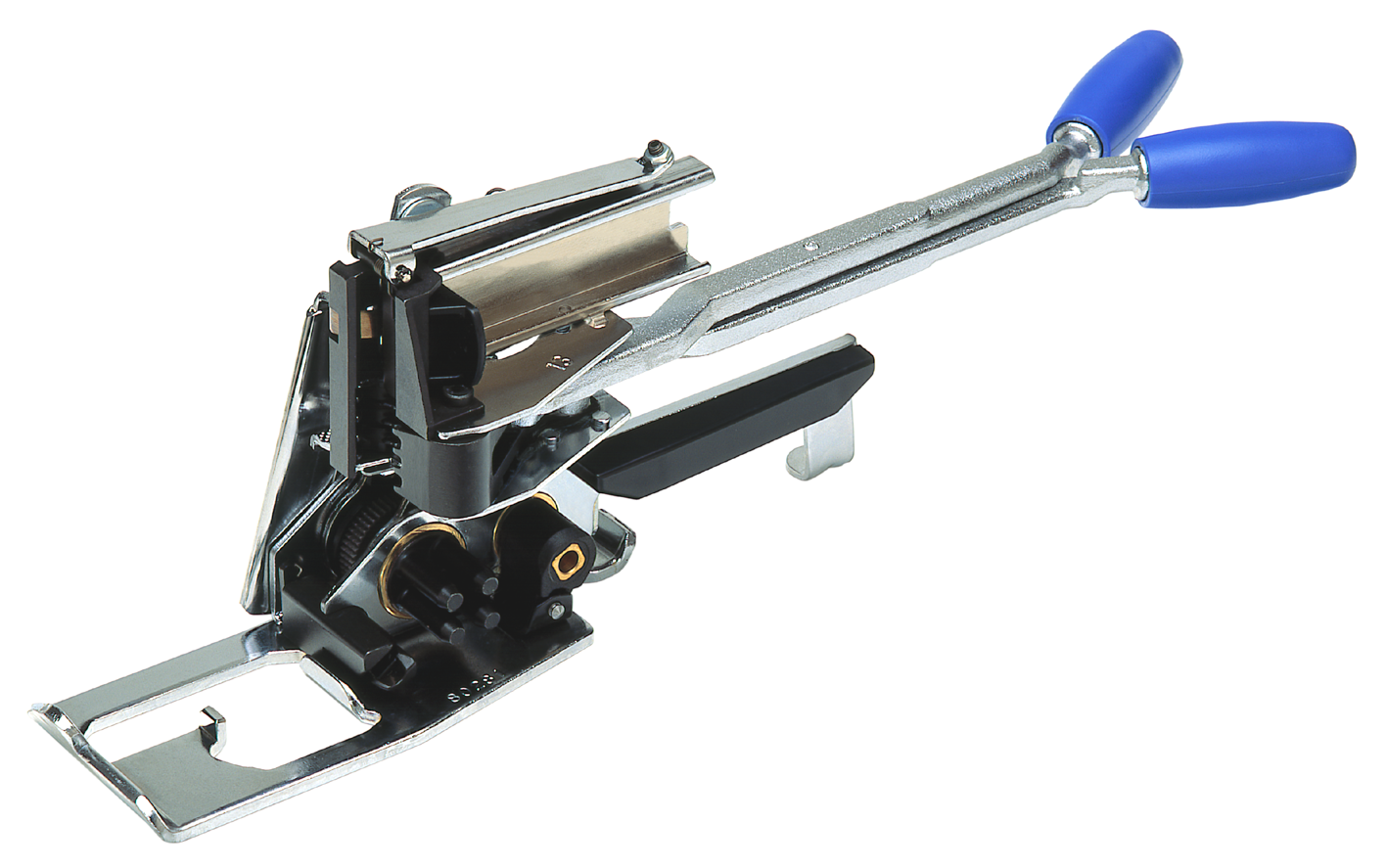

Strapping is placed around the package, the ends are fed into

the strapping tool , and pulled taut with a tensioning lever. The connection is then secured using

a sealing sleeve, clamp, or welding process, and the excess strap is neatly cut off.

What important safety rules apply when strapping?

Wear protective gloves when tensioning and cutting the tape , check the tension regularly, and inspect the device for functionality and cleanliness after each use. Use only the correct tape and seal types and follow the manufacturer's operating instructions to avoid injuries and transport damage.

How does a manual strapping tool work?

The tape is inserted into the device, pulled using the tensioning lever, and once tensioned, it is sealed tightly using the integrated mechanism or a locking sleeve. With combination devices , tensioning, sealing, and cutting are performed automatically in a single step .

What is the difference between PP strapping and PET strapping when strapping?

PP strapping is more flexible and primarily suitable for light to medium-weight packages , while PET strapping offers greater tensile strength and is used for heavy or sharp-edged loads. The tool settings and closure types must always be appropriate for the respective strap type.

What should be observed when operating a strapping tool?

The operating instructions for all equipment in the workplace must be available at all times and read by all employees. They include information on the area of application, hazards, maintenance intervals, what to do in the event of malfunctions, and protective measures , and are part of the occupational health and safety regulations.

Conclusion to our strapping tool & strapping band instructions

Strapping is a must for any warehouse that wants to ensure secure shipping. It can be used to

safely transport products of any size. With the right strapping and its proper use, you can ensure safe shipping. We've covered the different types of

strapping ,

safety tips when using strapping , and how to select the right size or type of strapping.

So, if you're looking for a reliable way to transport packages and pallets safely and securely, be sure to check out the wide range of options offered by Sandax ! With a range of lengths and sizes, Sandax covers all your business needs and makes your shipping a little more secure today! Feel free to contact us if you need advice on our strapping or tensioning devices !